Small Defect

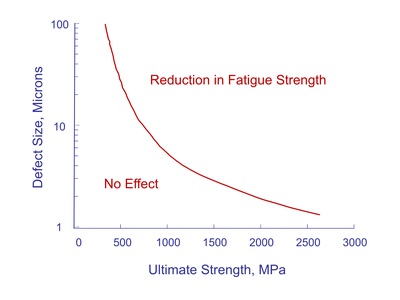

Traditional theories of fatigue evaluation based on either stress concentration factors or stress intensity factors are applicable to defects which can be seen with the naked eye, defects larger than about 1mm. Small artificial notches, such as surface defects like corrosion pits and scratches, naturally occuring defects and nonmetallic inclusions are all of practical importance. Some defects are too small to be of any importance and are non-damaging. The plot below shows the size of defect that will have an influence on the fatigue strength. This size is dependant on the strength of the material.

As the defect size decreases, traditional fatigue theories are longer accurate and special techniques must be used. Appropriate fatigue theories for small defects are presented here so that you can make a quantative estimate of the reduction in fatigue strength for a particular size and shape defect.