Welded Structures

Complex weld shapes and residual stresses require special fatigue considerations for welded structures. The heat from the welding process causes local tensile residual stresses at the weld toe, geometric distortions which lead to additional bending stress and changes in material properties near the weld. In addition, the local geometry along the weld toe varies along its length. Several approaches have been developed to analyze welded structures.

Nominal Stress

Nominal stress approaches are based on extensive tests of welded joints and connections. Weld joints are classified by type , loading and shape. For example, a transversely loaded butt weld. It is assumed and confirmed by experiments that welds of a similar shape have the same general fatigue behavior so that a single design SN curve can be employed for any weld class. The designer need only determine the nominal stress and select a weld class. There is no need to directly consider the stress concentration effects of the weld. Several nominal stress based classification systems exist and are included in eFatigue.

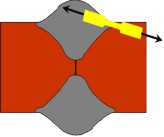

Structural Stress

Structural stress approaches are often referred to as "hot-spot methods". The structural stress includes the macroscopic stress concentrating effects of the weld detail but not the local peak stress caused by the notch at the weld toe. There are various methods used to determine the structural stress. They involve extrapolating the computed or measured stresses from two points near the weld to a structural stress at the weld toe. This method works in situations where there is no clear definition of the nominal stress.

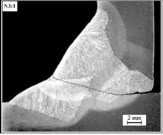

Local Stress/Strain

Local stress or strain approaches include both the macroscopic stress concentration due to the weld shape and the local stress concentration at the weld toe. To apply traditional methods of fatigue analysis to welds, an appropriate value of the stress concentration factor and residual stress must be selected. One common assumption that is often used is that the residual stress after welding is equal to the tensile yield strength of the material. The major influence on the stress concentration of a weld is local weld toe radius which varies along the length of the weld. Although the smallest radius produces the largest stress concentration factor, its effect in fatigue is smaller because of the gradient effect. As a result there is a critical radius for fatigue that can be used to compute the fatigue notch factor.

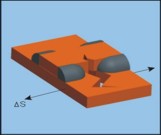

Crack Growth

Many weld details have planar lack of fusion defects. This is particularly true of fillet welds. In this case fracture mechanics models for crack growth are the most appropriate fatigue technology.

Fatigue Analyzers

Sign in or sign up to use these analyzers

日本語

日本語