Probabilistic

What does it mean to have a safety factor of 3? It is better than a safety factor of 2, but how does it relate to the risk and reliability of your design? And at what cost? Some people simply use lower bound material properties to account for variability. This simple minded approach ignores variability and uncertainties associated with loading, analysis and geometric variables. Probabilistic fatigue analysis is a much better tool to obtain estimates of the failure probability and to quantify the relative influence of variability and uncertainty in all of the input parameters so that the life drivers can be identified.

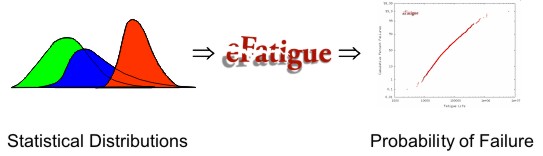

eFatigue determines failure probabilities by replacing deterministic values with statistical distributions for any of the input variables in the Constant Amplitude Calculators. The Probabilistic Calculators can be used in conjunction with more complex Fatigue Analyzers by defining an equivalent constant amplitude load.

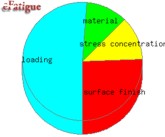

Outputs from the analysis include probability of failure plots as well as tables of probabilistic sensitivity factors. These factors quantify the relative variability or uncertainty of each input variable. This allows you to concentrate your resources on the ones that are the most important and have the most influence on the reliabiliy of your products.

Finders are provided to obtain the necessary input information for material properties and stress concentration or stress intensity factors. Guidance is provided to help you select appropriate statistical distributions and variability.

日本語

日本語